Electronics

At DC LAB Engineering, we specialize in designing and assembling custom electronics to meet your specific needs. Our team of experts is available to answer any questions you may have about our services. Contact us at info@dc-lab-engineering.eu to learn more.

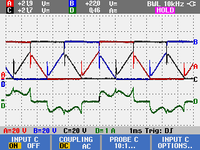

A few low voltage solutions are displayed below, and can be designed for a wide range of voltge levels:

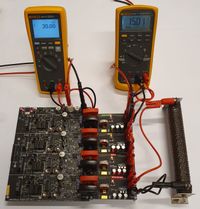

DC-Grid Droop Control

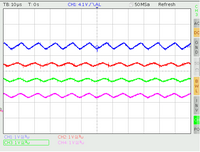

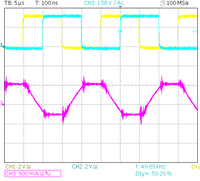

Dual Active Bridge

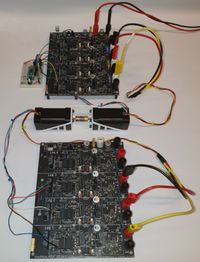

Coupled Motor Inverters

Assembly Service

Droop Control? DC droop control is a technique used in DC power systems to maintain a constant voltage across a load. It works by adjusting the output current of the power source in response to changes in load resistance. This helps to ensure that the voltage across the load remains constant, even as the load resistance changes. The Universal Four Leg enables droop control over four outputs. | Dual Active Bridge? A dual active bridge is a power conversion topology that allows for the efficient transfer of power between two DC voltage sources. It consists of two bridge circuits that are connected in parallel and controlled by a microcontroller. The dual active bridge can operate in a number of different modes, including voltage boosting, voltage bucking, and current balancing. The Universal Four Leg enables the Dual Active Bridge techniques. | Coupled Motors? Power can be transferred between two motors that are coupled together by connecting the two motors in series. When one motor is driven, it will rotate and transmit torque to the other motor, causing it to rotate as well. This allows for the transfer of power from one motor to the other, enabling them to work together to perform a task. The Universal Four Leg enables motor control and transfer power trough a system like this. | Pre-Assembly? The pre-assembly process involves preparing components and subassemblies for final assembly. This may include cleaning, inspecting, and testing components to ensure they meet specifications, as well as organizing and labeling them for ease of use during the final assembly process. Pre-assembly can help to streamline the assembly process and improve efficiency by reducing the need for rework and downtime. |